Hi I am Alkis, Product Design Engineer

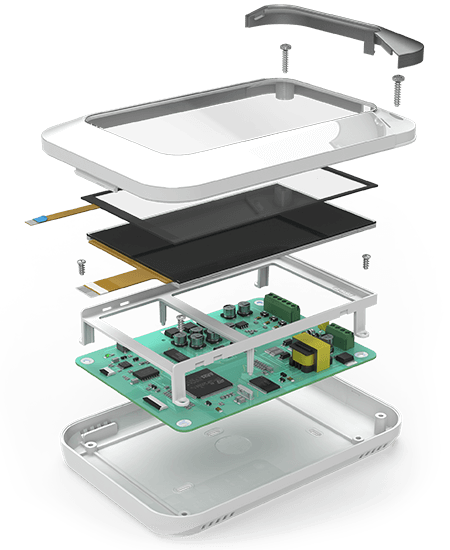

I develop products from concept to production. I have particular experience in injection moulding, electronic enclosures, automation and DFM.

About

PLEASE NOTE: This is a self-promotional website. For large periods I work in permanent positions and might not be available for freelancing work. Due to confidentiality and NDAs, most of my work cannot be posted online. I hope the above teasers will keep you engaged. Printed portfolio is available for private viewing.

Thank you for viewing my website. I am Alkis, I have been designing / engineering products since 2005, working full time in corporate or consultancy environment. Throughout the years I have worked for a wide range of Industries such as homeware, lighting, electronic enclosures, IT, medical devices, automation/robotics and tooling.

I have experience taking projects from concept to production and distribution and on continuous product improvement. Following the entire life cycle of a product has given me a very good perspective of what it takes to make them commercially successful. I have designed for start-ups and big corporations, either directly or through an agency/supplier. Some of them are, Lenovo, Thermo Fisher Scientific, Astro Lighting, D3O, Scott Sports, Nestle and Automata Technologies.

Methodology

New product development

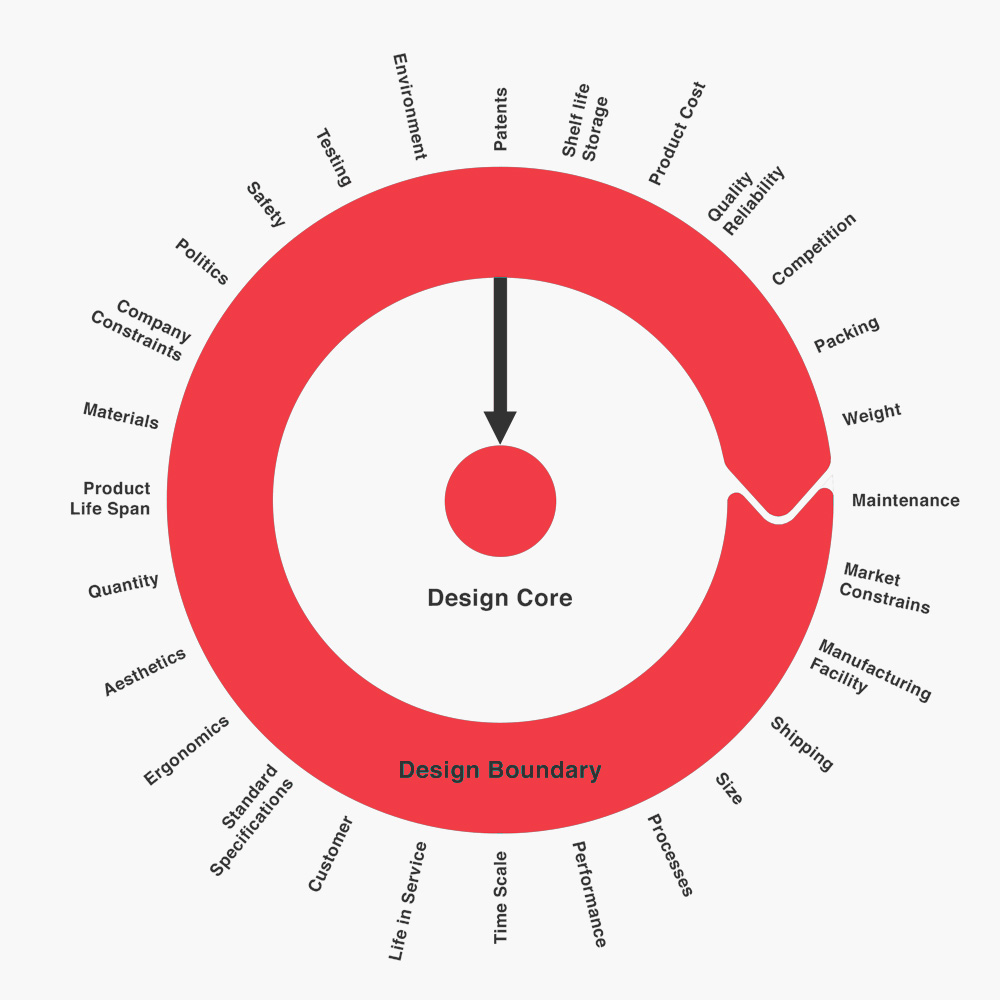

Every product is unique in its specifications and any design process needs to be flexible enough to accommodate those, without losing focus of the design intent. When developing a new product from scratch, I follow the universally acceptable method, where the designer conducts research and defines the design boundaries before proceeding to the actual design/engineering. Together with the principles of “total design” which examine all the aspects of a product holistically, this method aims to reduce the development time and risk.

This allows me to deliver products that are true to the requirements regardless of their complexity, satisfy the user needs and also deliver on the commercial requirements.

1. Discover

User research / Market research / Patent and technology research / Trend analysis / Identify user scenarios and existing products failure modes

2. Define

Brand requirements / C.M.F. / Project Management / Formulate Product Design Specifications

3. Develop

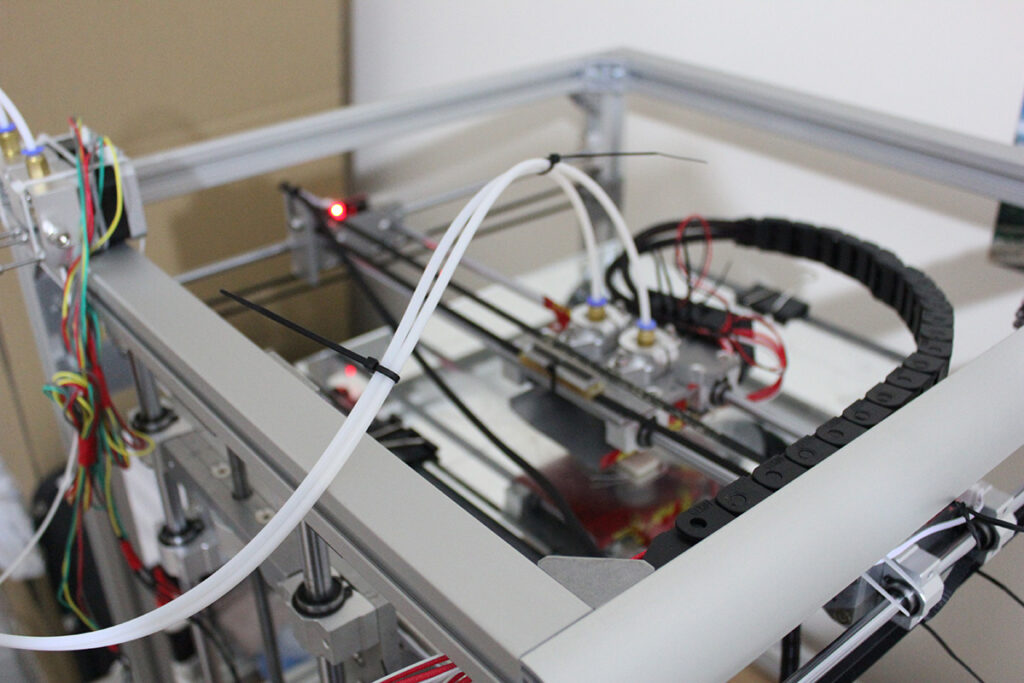

Conceptualize / Engineer and CAD / Detail for manufacturing / Rapid Prototyping

4. Deliver

Testing and trouble shooting for production / Deliver manufacturing envelope / Production follow-up

What I do

Services and Expertise

While I can follow the entire product development process, there are some areas where I excel and my services have the highest value/impact.

Design management & Full life cycle

Experience managing complicated projects and multidisciplinary teams. I have worked in startups that scaled up and can guide you in setting up the correct pipeline for your product development.

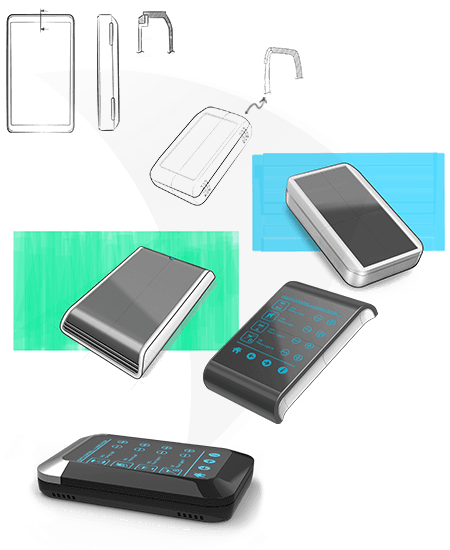

CAD / Surfacing

17 years of experience in CAD including large assemblies and organic surfacing for plastic products. No model is too complicated. I have a Rhinoceros 3D license for freelancing but have used a variety of other CAD through my employers.

Design for Manufacturing

I can design for manufacturing (DFM) from a concept stage or adapt the design to fit your in-house processes and specific manufacturing capabilities. A common issue in many companies is the clear divide between creative designers and pragmatic engineers. Designers will explore ideas that might not be manufacturable either due to lack of knowledge or so as not to restrict creativity. The product will then have to undergo a lengthy DFM and redesign step, by mechanical engineers, at a late stage in the development process. This can cause a small-budget startup to fail. Having worked as a designer, but also on the factory workflow, I am ideal at bridging this gap.

Engineering & Detailing

I have experience in several manufacturing methods and detailing CAD/engineering drawings for those. Some of those are injection moulding, open tool cast and tooling, sheet metal fabrication and precision engineering. I have designed complicated mechanisms and numerous electronic enclosures and IP rated products.

Location

I am based in the southwest outskirts of London but am also accustomed to working with clients all over the world.

I have a second base in Gongyixiqiao, Beijing (公益西桥,北京) for employers that can cover the work permit requirements.